HOW THE COMCAST TOWER COULD HAVE BEEN A NET ZERO BUILDING

- Michael Mullock

- Mar 8, 2022

- 3 min read

This hypothetical example is for educational purposes only.

It is based on actual data that we developed.

The Comcast Tower, project, as most center city buildings, could not use an on-site solar system but had access to green electric power.

The building, by architects Foster + Partners , was designed with an indoor swimming pool and a spa on the top floor for a hotel occupant: Four Seasons, Philadelphia.

IQ Radiant Glass Window Systems maximize the value of non-fossil fuel sources by significantly improving the use-efficiency of the electricity generated. The intrinsic value of Radiant Heating Glass window systems, increase the efficiency of electricity generated by non-fossil sources by 25-30%.

We Created a Pro Forma Analysis of Architectural and Mechanical Plans of the Multi-Use Glass Tower

The analysis compares and contrasts heating the glazed building envelope with an IQ Radiant Glass Window System versus natural gas mechanical heating :

First Cost

The installed cost of a natural gas steam/hot water distribution system and conventional windows were approximately equal to the installed cost of an IQ Radiant Glass Window System for the entirety of this building’s thermal envelope.

Annual Energy Operating and Distribution Cost

Using electrically heated glazing systems would have saved approximately $390,000 per year (a 25% annual energy savings, based on 2013 data).

Condensation Avoidance

A heated glazing system offers the best means of condensation avoidance in high humidity spaces such as Pool and Spa areas, as well as providing superb thermal comfort for the swimmers. ( No value Assigned)

Building Temperature and Building Management Control

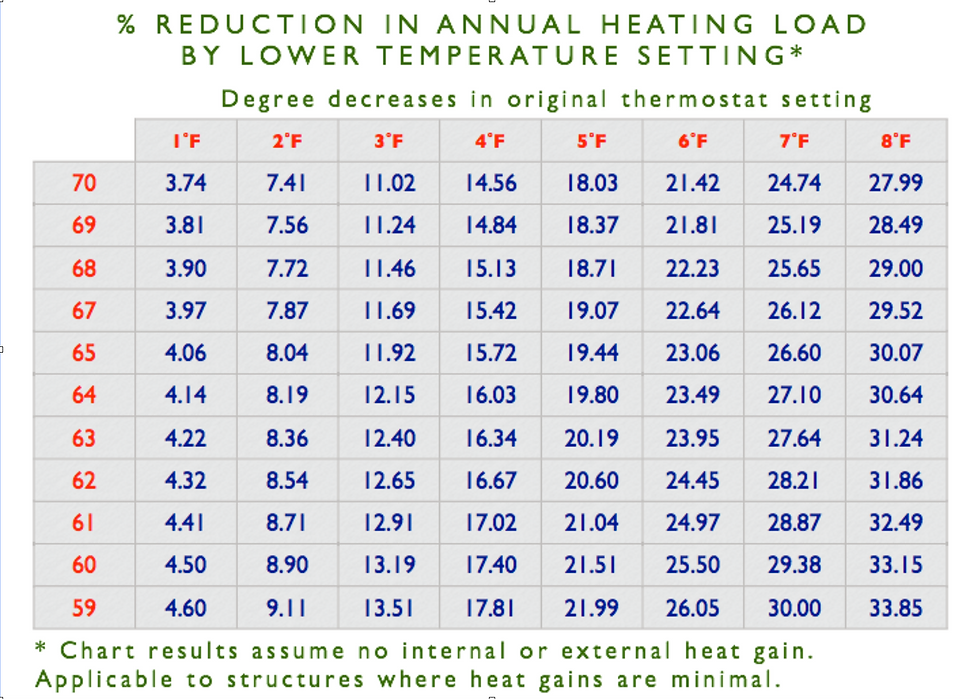

Electrically heated glass provides controllers with “software points” so that each. window is an individual heating zone. Areas requiring less heat can independently use less power. The radiant heat is focused on occupants and room contents. It is focused on where needed and when needed. Used as a hybrid with traditional systems. the overall ambient temperature will be reduced with no loss of thermal comfort. This has a significant impact on energy usage as shown in the chart below (Radiant Heating & Cooling Handbook, Chapman and Watson)

Steam/hot water heating of glass panes requires extensive valve controls, with remote sensors and floor by floor control panels. Costwise, mechanical control systems using “hardware” points can never match that of electronically controlled systems. We believe this is self-evident and requires no additional justification. ( No value Assigned)

Maintenance Cost & Longevity of Heated Glazing Systems

Heated Window Glazing Systems have no mechanical moving parts and require little or no annual maintenance. a

An annual savings of $500,000 a year can be anticipated.

Sustainability

The building with electricity sourced from non-fossil sources, would reduce its carbon foot print by 32,596,368 lbs. CO2 per year. ( No value Assigned)

Additional notes

The differential heating cost includes the use of hot water heat for air systems for both analyses, The only differentiation is electric versus natural gas fin tube heat for perimeter glazing.

The energy savings using electrically heated glazing systems are realized by the applied energy differences due to lower heat settings, lower u-values of the glass, efficiencies related to radiant heating glass and associated energy costs to deliver the heat to the building envelope thermal load.

Given that electrically heated glazing does not require pumps, fans, and the burden imposed by gas steam boilers, heat exchanger and piping losses, the annualized energy cost savings is not difficult to realize.

Summary:

The annual energy cost savings of electrically heated glazing was projected to yield approximately $400,000 per year in natural gas and electric savings (based on 2013 data). With the selection of off-site non-fossil sourced power

the building would have saved over 32,000,000 lb. of CO2 per year.

Comments